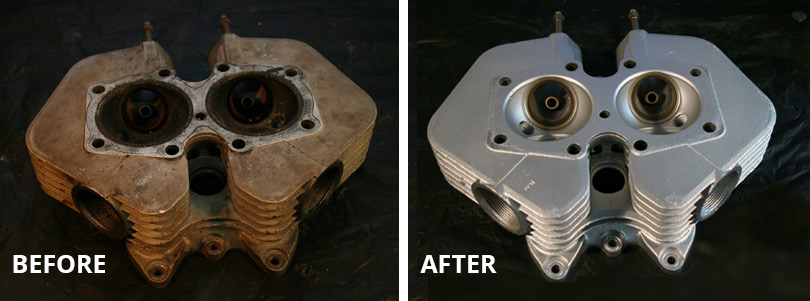

Vapor Blasting is a specialized process, which produces a very fine finish without damage to the component. It is especially effective on restoring parts with complex shapes where manual cleaning is difficult.

This process can be used on aluminum, brass, copper and bronze and can bring parts back to show quality.

Vapor blasting uses only environmentally safe media and water to wash away years, even decades of, oxidation, deterioration, and corrosion. The media is light and has the texture of very fine flour. It is mixed in the vapor blast machine with water and sent along the hose where air creates the vapor! The slurry mixture is pumped to the nozzle and the operator can get very close and gently clear away every bit hiding in the deepest crevices.

Unlike dry-grit blasting which is designed to fire media at high speeds and bounce off the surface the vapor-blast mixture is so soft it does not abrade away metal from your fine machined surfaces so it is unnecessary to mask those critical surfaces during blasting.

The action of the glass bead hammering the surface actually peens the surface pores closed, giving you a surface that is harder and more stain-resistant than when it was new.

Vapor Blasting is better than bead blasting! Better than soda blasting, tumbling and better than any amount of scrubbing, you can do by hand!